Hey,

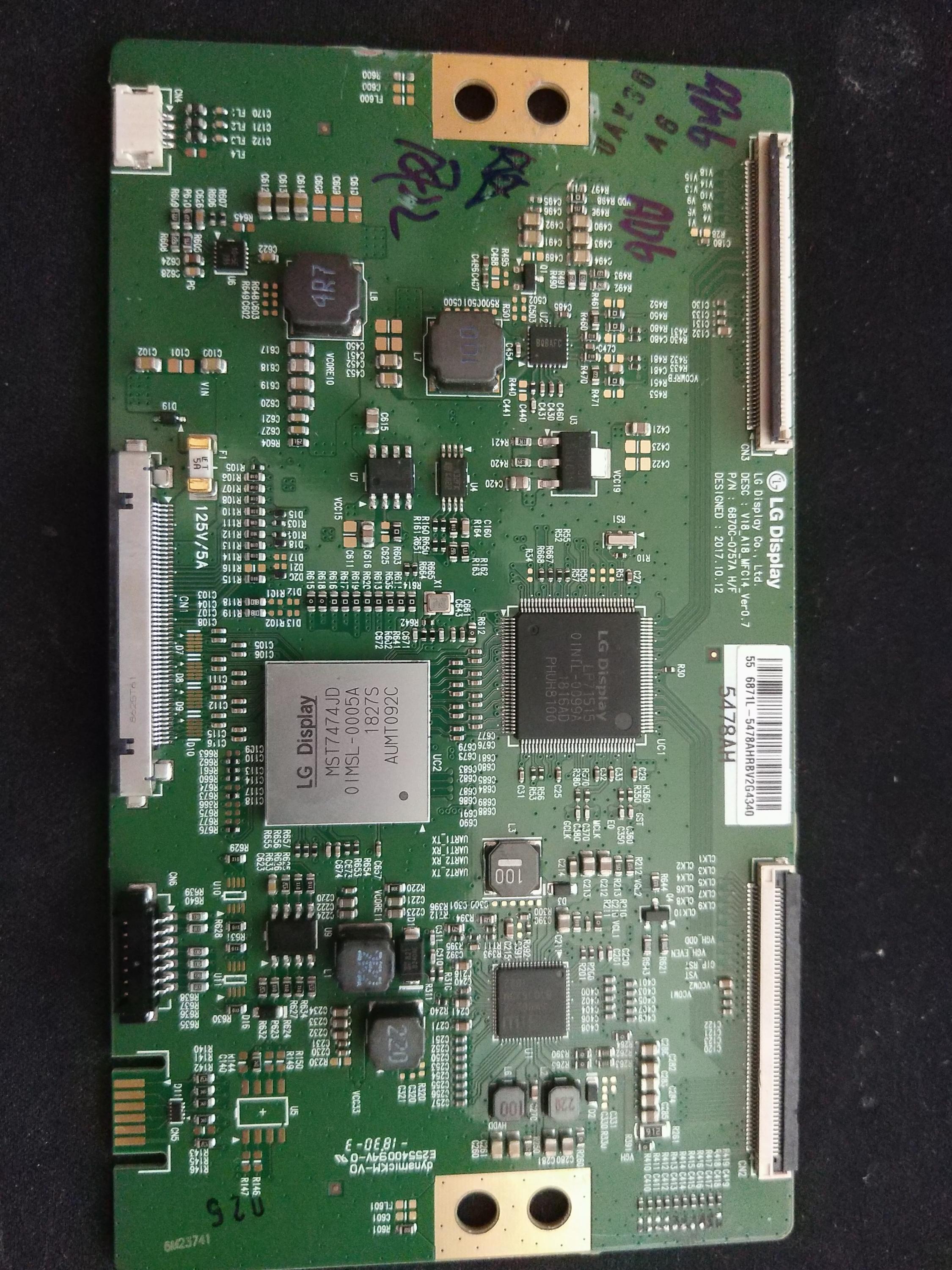

I'm working a TCON board for my TV, unfortunately, I am unable to source the part I need, however, with a bit of modification, a board from a smaller unit in the same line can work instead.

I have needed to remove some caps and eventually, swap out the EPPROM module between the two cards.

I've only ever really worked on wires and bigger bits, so this is my first time needing to remove parts off the board, I've removed an array of caps that are needed to be removed. but I think I've completely frigged it up already.

These are the pads from the removed caps:

It's work mentioning I don't need to replace these, so if I've not done any irripairable damage to the board, no problem other than need to really practice.

Also - an additional question. Could someone tell me where the EPPROM module on this board? I know they're usually six-pin chips but I can count a couple on this board and they look identical, the numbers on them are damn near impossible to read too.

Really appreciate the help

Warmest

I'm working a TCON board for my TV, unfortunately, I am unable to source the part I need, however, with a bit of modification, a board from a smaller unit in the same line can work instead.

I have needed to remove some caps and eventually, swap out the EPPROM module between the two cards.

I've only ever really worked on wires and bigger bits, so this is my first time needing to remove parts off the board, I've removed an array of caps that are needed to be removed. but I think I've completely frigged it up already.

These are the pads from the removed caps:

It's work mentioning I don't need to replace these, so if I've not done any irripairable damage to the board, no problem other than need to really practice.

Also - an additional question. Could someone tell me where the EPPROM module on this board? I know they're usually six-pin chips but I can count a couple on this board and they look identical, the numbers on them are damn near impossible to read too.

Really appreciate the help

Warmest

CAPs POOF

CAPs POOF

Comment