So this was running in a computer for a while, working fine. I went to do my every-other-day check to make sure fans are spinning, no clicking hard drives, etc. of all my computers running. I noticed that there was no fan exhaust on this machine. I shined a flashlight to see that the fan was not spinning. I thought that maybe it seized but thought that was strange because I always oil fans after I recap power supplies.

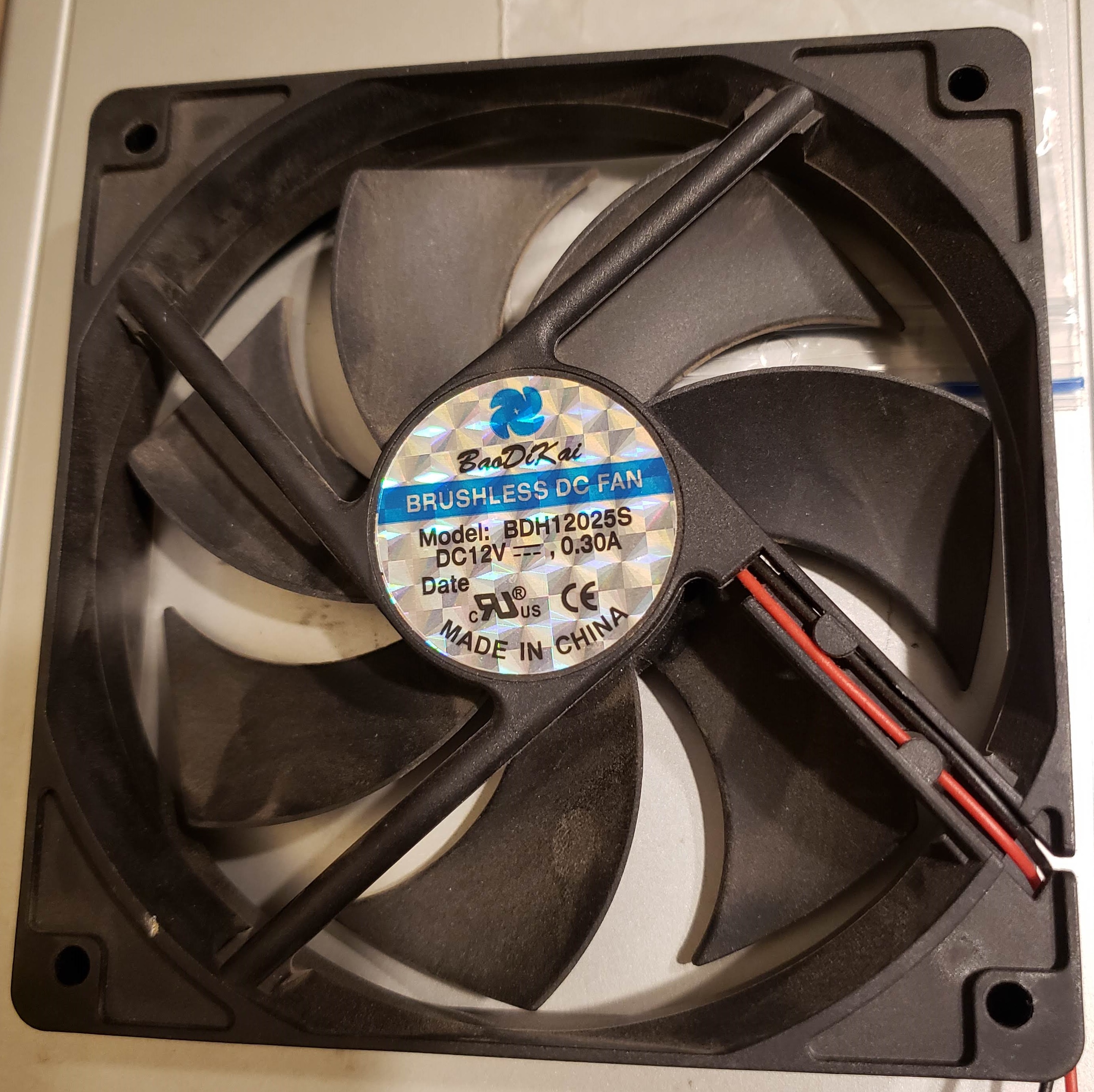

I thought that maybe it was the PSU but I pulled it and plugged it straight into the molex of another PSU. I tried 5V and 12V, nothing. No tick, it doesn't even try. Plugged into 12V and tried 'kick starting' it by manually spinning it but it has no life.

I got close to the bearing to see if I could smell anything burnt but it doesn't smell at all and spinning it with your finger, it spins very well. The sleeve bearing seems perfectly healthy. It was made in November 2011 but does not have a lot of use on it.

Has anyone had a cheap fan like this just die for no reason? It's a modded power supply but it seems odd that any refurbishing mods would cause a fan to die. It's just scary to think that a fan could die for no reason! Luckily the PSU was only powering an 80W load so even with no fan, it wasn't that warm.

I thought that maybe it was the PSU but I pulled it and plugged it straight into the molex of another PSU. I tried 5V and 12V, nothing. No tick, it doesn't even try. Plugged into 12V and tried 'kick starting' it by manually spinning it but it has no life.

I got close to the bearing to see if I could smell anything burnt but it doesn't smell at all and spinning it with your finger, it spins very well. The sleeve bearing seems perfectly healthy. It was made in November 2011 but does not have a lot of use on it.

Has anyone had a cheap fan like this just die for no reason? It's a modded power supply but it seems odd that any refurbishing mods would cause a fan to die. It's just scary to think that a fan could die for no reason! Luckily the PSU was only powering an 80W load so even with no fan, it wasn't that warm.

u can also stick a wooden stick or plastic straw in the fan grill to "help" the partly broken fan spin up.

u can also stick a wooden stick or plastic straw in the fan grill to "help" the partly broken fan spin up.

Comment