Okay, before I begin, let me note here that I am no expert on the matter. All of the info below is based on information that I found on the web, in capacitor datasheets, and some experiments I conducted myself.

So what is electrolytic capacitor reconditioning (also known as reforming)?

Basically, it is applying the maximum rated voltage on capacitor for a period of time. This is done in order to rejuvenate the electrolyte and/or aluminum oxide layer inside the capacitor.

Which electrolytic capacitors should be reformed?

- Ones that have been sitting in storage for a long time (regardless of whether they are new or used)

- Used capacitors that came from a circuit, where the operating voltage was much lower than the rated voltage of the capacitor.

Example: 6.3V electrolytic caps that were used on the CPU filter output of a motherboard (where the working voltage is often less than 1/3 to 1/4 of the rated voltage.)

Why should electrolytic capacitors be reformed?

According to Panasonic (information found in HFQ series datasheet):

Not only that, but a leaky cap (as in, capacitor with a high leakage current… not one that is physically leaking electrolyte) will usually trick your ESR meter to show lower ESR than what the capacitor may have. So if the cap has gone high ESR, your meter may not show it and you might end up putting a faulty cap back in service. To avoid this, check the capacitance of the cap. If it is higher than 20% of its specified capacitance, it is likely leaky and it is time to reform it. If you don't have an ESR or capacitance meter (like me  ), then definitely reform it so there won't be any doubts.

), then definitely reform it so there won't be any doubts.

How to reform electrolytic capacitors:

More from the same Panasonic datasheet:

I also saw some places online suggest to reform caps for 5 minutes (minimum) plus 1 minute for every month the cap was stored. Thus, as an example, a 4-year old stored cap would need to be reformed for 5 + (12 x 4) x 1 = 53 minutes. From my experiments, 2 hours seems to be good enough.

Now, reforming only one capacitor at a time is slow. Therefore, building a “cap reformer” to recondition multiple caps at a time should definitely speed things up. And this is pretty much the goal of this thread – to show some simple working examples to build your own.

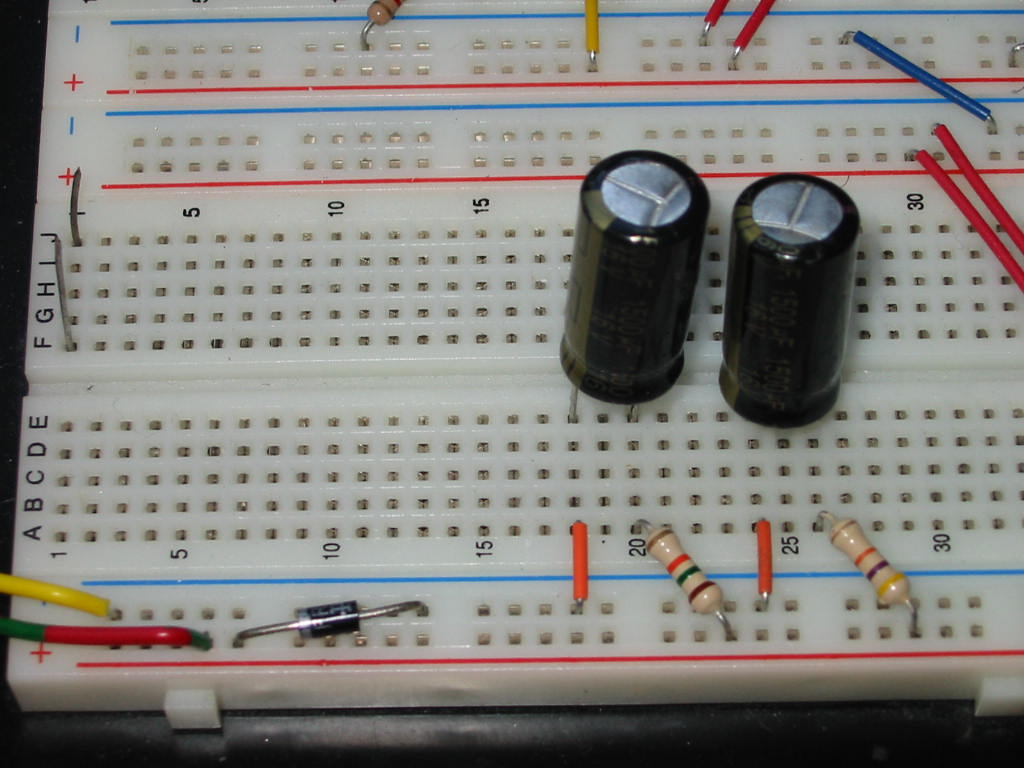

There are more than a few ways to do this. In general, all you will need is a handful of resistors and something to let you connect and disconnect the electrolytic caps easily from the cap reformer circuit. I used a breadboard for this. And here is what my cap reformer looked like:

(Note: I only have two caps in the above picture, but later I expanded my circuit to do up to 11 caps at a time.)

You could also use a ZIF IC socket in place of the breadboard (thanks to Per Hansson for suggesting this idea to me). It will be both cheaper and easier to reform caps with short leads or leads that have excess solder (with a breadboard, the leads must be long enough to go down in the contacts and be clean enough to fit in the breadboard holes)

So for the ZIF socket, something like this should do:

http://www.ebay.com/itm/2PCS-NEW-Hot...cAAOxyjxlTKpxV

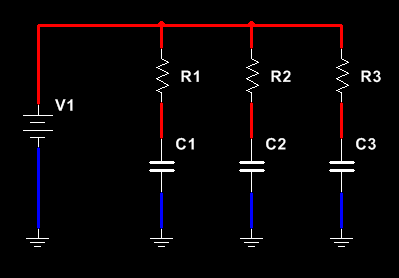

Then, just wire your cap reformer circuit. Schematic below if you're not quite sure what to do here:

In the circuit above, capacitors C1, C2, and C3 are the electrolytic capacitors that are to be reformed, while resistors R1, R2, and R3 are the series current-limiting resistors for each cap respectively. Of course, you can size your cap reformer to do as many caps at a time as you want. Just add a series resistor for every cap you add (i.e. continue the pattern to the right with the above circuit).

As per the Panasonic datasheet again, the series resistors can all be 1 KOhm. However, according to some tests I did, it may be better to use higher resistances if the caps to be reformed are very old (as in, 10+ years in storage) or if they were used with a much lower voltage than their rated voltage (again, motherboard CPU caps should come to mind here), otherwise they may develop and internal short-circuit. For my reformer, I used mostly 10 KOhm resistors (but also tried a few 15 KOhm and 47 KOhm ones). Just about anything between 1 KOhms and 100 KOhms will work, since this is nowhere near exact science. From my experiments, however, the further you go above 10 KOhms, the longer it takes for the caps to charge (especially for ones over 1000 uF), and this will slow down the reform process or won't reform the capacitors to the maximum voltage you selected with the source.

With that being said, if you find that some of your caps have not reached 90% of the source voltage after 30 minutes of reforming, then one of the following could be happening:

(1) The series resistor has too large of a resistance for the capacitor it is reforming

(2) The cap is possibly excessively leaky

(3) A combination of the two above

The best solution for this would be to lower the resistance of the series resistor. However, do NOT use less than 1 KOhms (except possibly for very large caps, like 400V, 500 uF… or 25V, 4700 uF). If the cap still does not reach 90% of the source voltage after this, you should test the cap's leakage current and compare to datasheet maximum (see Leakage Current thread). And if the cap shows only a few mV to 1V across its terminals after a minute or so of reforming – STOP! The capacitor has likely become short-circuited internally. Depending on your multimeter, you *may* be able to verify this by measuring the resistance. But don't count on it. I had a few caps short-circuit, and while some read as low as just several Ohms, one read 1.8 KOhms (which is far from a short-circuit… but if you put this cap in a device and apply power, it will likely short almost immediately. Some of mine did when I used a lower series resistor.)

To be continued... (10000 characters limit)

So what is electrolytic capacitor reconditioning (also known as reforming)?

Basically, it is applying the maximum rated voltage on capacitor for a period of time. This is done in order to rejuvenate the electrolyte and/or aluminum oxide layer inside the capacitor.

Which electrolytic capacitors should be reformed?

- Ones that have been sitting in storage for a long time (regardless of whether they are new or used)

- Used capacitors that came from a circuit, where the operating voltage was much lower than the rated voltage of the capacitor.

Example: 6.3V electrolytic caps that were used on the CPU filter output of a motherboard (where the working voltage is often less than 1/3 to 1/4 of the rated voltage.)

Why should electrolytic capacitors be reformed?

According to Panasonic (information found in HFQ series datasheet):

5. Long Term Storage

Leakage current of a capacitor increases with long storage times. The aluminium oxide film deteriorates as a function of temperature and time. If used without reconditioning, an abnormally high current will be required to restore the oxide film. This current surge could cause the circuit or the capacitor to fail.

Leakage current of a capacitor increases with long storage times. The aluminium oxide film deteriorates as a function of temperature and time. If used without reconditioning, an abnormally high current will be required to restore the oxide film. This current surge could cause the circuit or the capacitor to fail.

), then definitely reform it so there won't be any doubts.

), then definitely reform it so there won't be any doubts. How to reform electrolytic capacitors:

More from the same Panasonic datasheet:

Capacitor should be reconditioned by applying rated voltage in series with a 1000 Ω, current limiting resistor for a time period of 30 minutes.

Now, reforming only one capacitor at a time is slow. Therefore, building a “cap reformer” to recondition multiple caps at a time should definitely speed things up. And this is pretty much the goal of this thread – to show some simple working examples to build your own.

There are more than a few ways to do this. In general, all you will need is a handful of resistors and something to let you connect and disconnect the electrolytic caps easily from the cap reformer circuit. I used a breadboard for this. And here is what my cap reformer looked like:

(Note: I only have two caps in the above picture, but later I expanded my circuit to do up to 11 caps at a time.)

You could also use a ZIF IC socket in place of the breadboard (thanks to Per Hansson for suggesting this idea to me). It will be both cheaper and easier to reform caps with short leads or leads that have excess solder (with a breadboard, the leads must be long enough to go down in the contacts and be clean enough to fit in the breadboard holes)

So for the ZIF socket, something like this should do:

http://www.ebay.com/itm/2PCS-NEW-Hot...cAAOxyjxlTKpxV

Then, just wire your cap reformer circuit. Schematic below if you're not quite sure what to do here:

In the circuit above, capacitors C1, C2, and C3 are the electrolytic capacitors that are to be reformed, while resistors R1, R2, and R3 are the series current-limiting resistors for each cap respectively. Of course, you can size your cap reformer to do as many caps at a time as you want. Just add a series resistor for every cap you add (i.e. continue the pattern to the right with the above circuit).

As per the Panasonic datasheet again, the series resistors can all be 1 KOhm. However, according to some tests I did, it may be better to use higher resistances if the caps to be reformed are very old (as in, 10+ years in storage) or if they were used with a much lower voltage than their rated voltage (again, motherboard CPU caps should come to mind here), otherwise they may develop and internal short-circuit. For my reformer, I used mostly 10 KOhm resistors (but also tried a few 15 KOhm and 47 KOhm ones). Just about anything between 1 KOhms and 100 KOhms will work, since this is nowhere near exact science. From my experiments, however, the further you go above 10 KOhms, the longer it takes for the caps to charge (especially for ones over 1000 uF), and this will slow down the reform process or won't reform the capacitors to the maximum voltage you selected with the source.

With that being said, if you find that some of your caps have not reached 90% of the source voltage after 30 minutes of reforming, then one of the following could be happening:

(1) The series resistor has too large of a resistance for the capacitor it is reforming

(2) The cap is possibly excessively leaky

(3) A combination of the two above

The best solution for this would be to lower the resistance of the series resistor. However, do NOT use less than 1 KOhms (except possibly for very large caps, like 400V, 500 uF… or 25V, 4700 uF). If the cap still does not reach 90% of the source voltage after this, you should test the cap's leakage current and compare to datasheet maximum (see Leakage Current thread). And if the cap shows only a few mV to 1V across its terminals after a minute or so of reforming – STOP! The capacitor has likely become short-circuited internally. Depending on your multimeter, you *may* be able to verify this by measuring the resistance. But don't count on it. I had a few caps short-circuit, and while some read as low as just several Ohms, one read 1.8 KOhms (which is far from a short-circuit… but if you put this cap in a device and apply power, it will likely short almost immediately. Some of mine did when I used a lower series resistor.)

To be continued... (10000 characters limit)

). Again, I am no expert on this matter, so if anyone finds any mistakes or has any suggestions, please feel free to share them here.

). Again, I am no expert on this matter, so if anyone finds any mistakes or has any suggestions, please feel free to share them here.

.

.

Comment